If you grew up spinning wrenches on small-block V8s, working on electric cars can feel like stepping onto a different planet. The principles of suspension, tires, and brakes haven’t changed, but everything around the battery and high‑voltage system has, and the consequences of getting it wrong are much higher. This guide walks you through how to work on electric cars safely, what you can realistically DIY, when to call a pro, and what it takes to build a career in EV repair.

Electric cars: more laptop than lawnmower

Why working on electric cars is different

On the surface, working on electric cars looks a lot like working on any late‑model vehicle: remove panels, follow service procedures, plug in a scan tool. Underneath, the stakes are higher. A typical EV traction battery operates at 350–400 volts, and newer platforms are pushing 800‑volt architectures for faster charging and higher efficiency. That’s more than enough to be deadly if mishandled.

Where EVs are simpler

- No oil changes, spark plugs, timing belts, or exhaust.

- Far fewer moving parts in the drivetrain.

- Brake wear is reduced thanks to regenerative braking.

Where EVs are more complex

- High‑voltage battery packs and orange‑cable circuits.

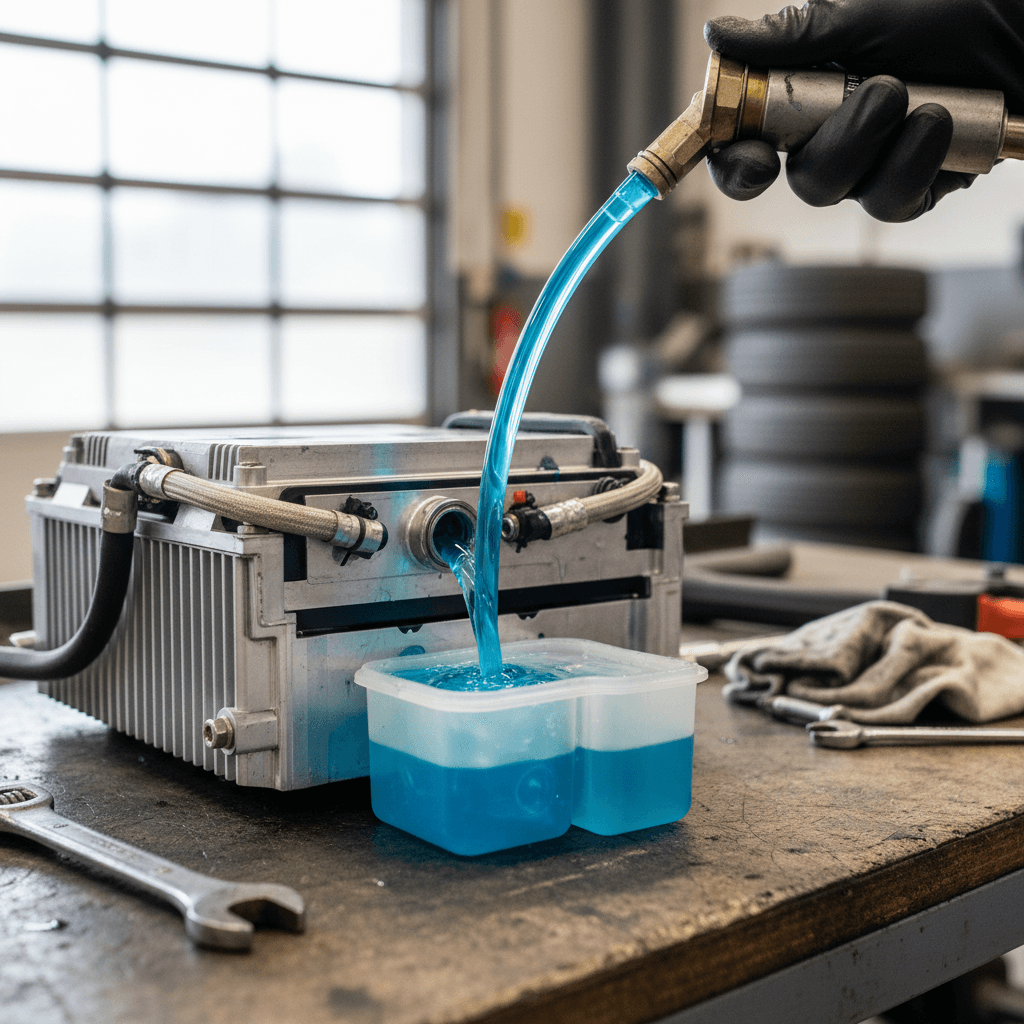

- Multiple cooling loops for battery, motors, and power electronics.

- Sophisticated software, over‑the‑air updates, and telematics.

Respect the orange cables

High‑voltage EV safety basics you cannot ignore

Before you think about working on electric cars beyond basic maintenance, you need to understand how the industry thinks about electrical safety. In the U.S., OSHA regulations and the NFPA 70E "Standard for Electrical Safety in the Workplace" underpin most professional guidance. You don’t need to memorize code books, but you do need to internalize a few non‑negotiable rules.

Key realities of EV electrical safety

- De‑energize whenever possible. Professionals follow lockout/tagout procedures to disconnect, secure, and verify systems are truly de‑energized before working on them.

- Assume it’s live until you prove it isn’t. That means testing with a properly rated meter, not just trusting a dash indicator or app.

- Use the right PPE. Insulated gloves, arc‑rated clothing, face shields, and insulated tools are standard for high‑voltage work in professional shops.

- Respect boundaries. NFPA 70E defines approach boundaries around energized parts, unqualified people are not supposed to cross them. In practical terms: if you’re not trained, don’t be in the battery bay.

Non‑negotiable rule

What you can safely do yourself on an electric car

The good news is that most of the routine, low‑risk work on an EV looks familiar and is within reach for a reasonably handy owner. Think "chassis and interior," not "orange wires and coolant manifolds around a live battery." Here are jobs that are typically safe for a DIYer, as long as you follow the vehicle manual and basic safety practices.

EV jobs that are usually DIY‑friendly

Stick to low‑voltage and mechanical systems; leave high‑voltage alone.

Tires & wheels

- Tire rotations on jack stands.

- Seasonal wheel swaps.

- Checking pressures & tread depth.

Brakes & suspension checks

- Pad inspections through the caliper window.

- Visual checks for leaks or torn bushings.

- Listening for clunks and squeaks.

Cabin filters & basics

- Cabin air filter replacement.

- Wiper blades and washer fluid.

- Interior trim and cabin storage mods.

Checklist: Before you wrench on an EV at home

1. Read the EV’s service or owner’s manual

Look for sections on "high‑voltage precautions" and follow any warnings about where you should not poke around.

2. Power the vehicle down properly

Shut the car off, remove the key or fob from the interior, and wait the manufacturer‑specified time for contactors to open before working near electrical components.

3. Stay away from orange cables and sealed packs

If a job requires you to unplug, unbolt, or move anything marked in orange, it’s not a DIY job unless you’re qualified.

4. Use quality jack stands and lift points

EVs are heavy thanks to their battery packs. Always use proper lift points and rated stands to avoid damage or injury.

5. Keep software changes conservative

Changing settings is fine; attempting to defeat safety interlocks, unlock extra power, or hack charging systems is a different story entirely.

Smart DIY strategy

Jobs only a qualified EV technician should do

There’s a hard line between sensible DIY and work that belongs in the hands of someone with EV‑specific training, insulated tools, and a live‑work procedure binder. If the job touches the traction battery, power electronics, or core safety systems, treat it as professional territory.

EV repairs that are not DIY projects

If a job involves these systems, plan on using a qualified shop or dealer.

| System | Examples of work | Why it’s pro‑only |

|---|---|---|

| High‑voltage battery pack | Module replacement, pack opening, cell balancing, contactor replacement | Exposure to lethal voltage, risk of thermal runaway, specialized test gear required. |

| High‑voltage cabling & connectors | Replacing orange cables, repairing HV connectors, isolating ground faults | Requires insulation resistance testing and strict PPE/lockout procedures. |

| Power electronics | Onboard charger, DC‑DC converter, inverter, motor controller repair | Packed with high‑energy components that can hold dangerous charge even when disconnected. |

| Fast‑charging hardware | Charge port replacement, CCS/NACS hardware faults, DC fast‑charge issues | Involves HV isolation checks and standards‑specific test routines. |

| Safety‑critical software | Airbag/ABS/ESC coding, battery management firmware, HV isolation monitoring | Incorrect coding can disable safety systems or compromise battery protection. |

For most owners, the cost of a pro is trivial compared with the cost of a mistake on high‑voltage hardware.

The YouTube problem

Tools and equipment for working on electric cars

If you’re serious about working on electric cars, whether as an advanced hobbyist or aspiring professional, you’ll need tools that are a step above the rusty socket set in your trunk. Some are familiar; others are borrowed from the world of industrial electrical work.

Core tools for safe EV work

Start with mechanical fundamentals, then add properly rated electrical gear.

Quality mechanical set

Insulated tools

Class 0+ gloves

Cat III/Cat IV multimeter

About PPE categories

Training and careers working on electric cars

If your interest in working on electric cars goes beyond weekend tinkering, you’re in good company. Automakers, independent shops, and charging‑network operators are all fighting for a limited pool of EV‑literate technicians. That shortage translates into opportunity, if you’re willing to invest in training.

Paths into working on electric cars professionally

Mechanical techs transitioning to EVs

Start with OEM EV familiarization courses and high‑voltage awareness training.

Get certified on basic EV service procedures: coolant loops, brakes, tires, and 12‑volt systems.

Progress to high‑voltage isolation checks and contactor diagnostics under supervision.

New entrants & students

Enroll in a community college or trade program with dedicated EV or advanced propulsion courses.

Complete general automotive service training, then specialize in EV systems and diagnostics.

Seek internships at EV‑focused shops, fleets, or companies like Recharged that work with used EVs daily.

Electrical & industrial background

Leverage existing high‑voltage safety knowledge (NFPA 70E, lockout/tagout) and adapt it to vehicle platforms.

Pursue OEM or third‑party training focused on EV power electronics and charging systems.

Look at roles in charging infrastructure deployment, battery diagnostics, and fleet energy management.

The EV technician of the next decade is part mechanic, part electrician, part software whisperer, and the market desperately needs more of them.

Where Recharged fits in

Inspecting and servicing used EVs

Used electric cars are where the romance of EV tech meets the reality of age, mileage, and previous owners. Working on them, whether as a buyer, seller, or technician, means paying attention to different failure modes than you’d see on a ten‑year‑old gasoline sedan.

Key inspection points on a used EV

- Battery health: State of charge vs. displayed range, degradation history, DC fast‑charge usage.

- Charging behavior: Does it charge reliably at home and on public fast chargers?

- Cooling systems: Evidence of leaks, pump noise, or poor thermal management.

- Undercarriage & pack: Corrosion, impact damage, or poorly repaired collision work near the battery tray.

How Recharged de‑risks the process

Recharged runs every vehicle through an EV‑specific diagnostic process, including battery health testing, charging‑system checks, and a detailed road test. The results roll into the Recharged Score, so you’re not guessing about the single most expensive component on the car.

If you’re trading in or consigning an EV through Recharged, that same process helps you justify fair market pricing to buyers.

Checklist: Smart approach to working on a used EV

1. Get a baseline battery health report

Use manufacturer tools, third‑party diagnostics, or a Recharged Score Report to understand current capacity and any stored battery‑related faults.

2. Verify charging on multiple stations

Confirm that the car charges properly on Level 2 and, if equipped, DC fast chargers before tearing into hardware.

3. Fix small, low‑risk items first

No‑start due to a weak 12‑volt battery? Cosmetic issues? Suspension clunks? Address these before you even think about touching high‑voltage hardware.

4. Document everything

On a vehicle that may later be sold or traded to Recharged or another marketplace, detailed repair records make your work more trustworthy and the car easier to value.

FAQ: Working on electric cars

Frequently asked questions about working on electric cars

The bottom line on working on electric cars

Working on electric cars demands a different mindset than the analog era of carburetors and distributor caps. You gain simplicity in some areas and inherit very real high‑voltage risk in others. The smart move is to split the work: handle the straightforward mechanical and cosmetic jobs yourself, build your knowledge with credible training, and partner with qualified EV specialists when the orange cables and battery packs enter the picture.

Whether you’re a curious DIYer, a technician planning your next career move, or a shopper sizing up a used EV, it pays to know where your comfort zone ends. Companies like Recharged exist to bridge that gap, by testing battery health, pricing vehicles transparently, and giving both buyers and sellers access to people who live and breathe EVs. Respect the voltage, stay curious, and you can have a long, safe, and rewarding relationship working on electric cars.