Open the hood on a modern electric car and you won’t see pistons or a radiator cap, but make no mistake, electric car battery cooling is every bit as critical as engine cooling was in the old world. Get it right and your EV charges quickly, delivers consistent range, and keeps its battery healthy for years. Get it wrong and you’re staring at throttled fast‑charging, accelerated degradation, and ugly resale value.

Quick definition

Why electric car battery cooling matters

Lithium‑ion cells are like athletes: they perform brilliantly, but only within a tight temperature band. Push them too hot or too cold and they sulk, burn energy inefficiently, and age faster than they should. That’s why modern EVs devote serious hardware and software to battery thermal management, often tying it into the cabin HVAC so the car can shuffle heat around like a climate‑controlled bank vault.

How temperature and cooling affect your EV

The battery’s temperature sweet spot

Most EV batteries are happiest roughly in the 20–35°C (68–95°F) range. Below that, internal resistance rises, chemistry slows, and you lose power and range. Above it, you start to invite faster degradation and, in extreme cases, safety concerns. The exact numbers vary by chemistry, but the pattern doesn’t.

- Too cold (below ~0°C / 32°F): Charging is limited or disabled, power output drops, and range shrinks.

- Comfort zone (roughly 20–35°C / 68–95°F): Best mix of performance, range, and long‑term health.

- Too hot (above ~45–50°C / 113–122°F): The car may reduce power and charging speed to protect the cells; long‑term exposure accelerates degradation.

Heat is the silent battery killer

Common EV battery cooling systems

Automakers have tried several approaches to EV battery cooling. Some worked beautifully; others, in hindsight, belong in the museum next to the carburetor. Broadly, you’ll see four main strategies in cars on the road today:

Four main battery cooling strategies

Each has trade‑offs in cost, complexity, and longevity

Liquid cooling

Coolant (often water‑glycol) flows through channels or plates under or between cells, pulling heat out and sometimes warming them in winter.

Pros: Precise, even temperature control, supports fast charging, good for large packs.

Cons: More complex, hoses and pumps can fail, needs careful sealing.

Forced‑air cooling

Fans blow air across or through the pack, often using cabin or outside air.

Pros: Simple and cheap.

Cons: Limited heat capacity; can struggle in very hot climates or under repeated fast‑charging.

Passive / natural cooling

Relies on conduction to the pack case and natural airflow under the car. No active fans or fluid.

Pros: Very simple, low cost.

Cons: Poor heat control; largely abandoned in modern EVs except small packs.

Hybrid / advanced systems

Combines liquid cooling with phase‑change materials (PCM) or clever heat‑pump integration to move heat around the car efficiently.

Pros: High performance, can share heat with cabin for efficiency.

Cons: Hardware and software complexity, still evolving quickly.

Liquid battery cooling: the modern standard

If you’re shopping for an EV built in the last few years, especially anything capable of serious DC fast‑charging, chances are its pack is liquid‑cooled. Think of it as a radiator system flipped on its head and flattened under the floor.

How liquid cooling works

- Coolant flows through cold plates or narrow channels running under/around the cells.

- A pump circulates this fluid to a small radiator or chiller tied into the car’s AC system.

- Sensors watch cell and coolant temps, while software adjusts flow and HVAC load.

- In cold weather, the same plumbing can warm the pack using waste heat or a heat pump.

Real‑world examples

- Tesla’s Model 3/Y and many legacy models use serpentine coolant loops snaking between cell groups.

- Most newer crossovers, from Hyundai Ioniq 5 to Ford Mustang Mach‑E, use plate‑style liquid cooling to support high‑power fast charging.

- The 2026 Nissan Leaf, after years of criticism for early air‑cooled packs, finally switched to a liquid‑cooled 75‑kWh pack to avoid past heat‑related issues.

Why liquid cooling dominates

Air-cooled batteries and legacy designs

Some early mass‑market EVs tried to save cost and complexity by skipping sophisticated liquid cooling. The original Nissan Leaf is the classic example: a largely passive, air‑influenced pack that did fine in mild climates, but saw accelerated degradation in desert heat and with frequent DC fast charging.

During normal commuting and Level 2 charging, these packs might not overheat dramatically, which is why some owners in cooler regions reported acceptable longevity. But push them, long highway climbs, repeated quick‑charging in summer, and the temperatures climbed faster than the car could shed the heat. The result was more capacity loss over time compared with similar‑age, liquid‑cooled competitors.

Know the history

Heat pumps and integrated thermal systems

The latest EVs don’t treat the battery as a separate climate problem. Instead, they blend cabin HVAC, power electronics, and battery cooling into one big thermal chessboard. The rise of automotive heat pumps is central to this story.

How integrated thermal systems juggle heat

Modern EVs treat heat as a resource, not just a waste product

Share heat

Heat from the motor or inverter can be recycled to warm the battery on a cold morning, improving charging speed and efficiency.

Heat pump magic

A heat pump can move heat into or out of the cabin and battery loop, using far less energy than simple resistive heaters.

Smart control

Software decides where each BTU belongs, cabin comfort, battery conditioning, or dumping it overboard, based on your drive and charge plan.

Preconditioning and apps

Cooling, fast charging, and performance

The moment you plug into a 150 kW DC fast charger, your battery becomes a furnace. Shoving energy in that quickly generates substantial heat within the cells, and cooling is the limiting factor on how long the car can sustain top charging speeds.

What you see as a driver

- Charge curve starts high, then tapers as the battery fills or gets hot.

- On a hot day, you may see slower charging than on a cool morning at the same station.

- Back‑to‑back fast‑charge sessions on a road trip often get slower as heat builds up.

What the car is doing behind the scenes

- Monitoring cell and coolant temps dozens of times per second.

- Spinning pumps and fans, possibly running the AC compressor to chill coolant.

- Lowering charge power automatically to avoid crossing critical temperature thresholds.

Smarter road‑trip habits

How cooling affects battery lifespan and resale value

Long‑term, battery cooling is not a spec‑sheet party trick; it’s the quiet determinant of how much usable capacity you still have at 80,000 or 150,000 miles. Two cars with similar mileage can have wildly different real‑world range if one pack spent years flirting with high temperatures.

Cooling behaviors that help your battery age gracefully

Avoid repeated hot fast‑charges

There’s nothing wrong with using DC fast charging, but stringing together high‑power sessions on a scorching day is the worst‑case scenario for pack temperature.

Don’t store the car full and hot

Parking at 100% charge in the summer sun after a highway blast is hard on cells. If you can, end hot days around 60–80% instead of 100%.

Let the car finish its cooling cycle

Some EVs run pumps and fans for a bit after you park. Let them work; that post‑drive cooldown is cheap insurance.

Use scheduled charging

Charging to your daily target just before departure means the pack sits less time at higher state of charge, often at optimal temperature.

How Recharged helps

Solid-state batteries and the future of cooling

Solid‑state batteries promise higher energy density and better inherent safety, and they’re inching closer to real EVs. But they don’t magically solve thermal management. In some ways, they make it trickier.

Many solid electrolytes conduct heat poorly, and large packs can develop local hot spots because there’s no liquid sloshing through to smooth out temperature differences. Interface layers between solid electrolyte and electrodes can add thermal resistance, trapping heat right where current is densest.

What changes, and what doesn’t, with solid-state cooling

Future tech, same basic physics

New materials, familiar constraints

Even if solid‑state cells tolerate higher temps before safety becomes a concern, aging and performance are still temperature‑sensitive. Expect carefully engineered cooling plates and interface materials, not the absence of cooling.

More localized thermal control

Designers may need to focus less on bulk coolant flow and more on extracting heat from specific regions inside modules, using techniques like micro‑channels, heat pipes, or phase‑change materials.

Bottom line on future packs

What to look for in battery cooling when buying used

Shopping for a used EV in 2025 means you’re staring at two very different generations of battery cooling philosophy. Here’s how to tilt the odds in your favor.

Liquid-cooled vs air-cooled used EVs at a glance

How cooling design shapes real‑world ownership on the used market

| Cooling type | Typical vehicles | Fast-charging behavior | Hot-climate risk | What a savvy buyer does |

|---|---|---|---|---|

| Modern liquid-cooled | Most newer crossovers and sedans (Tesla Model 3/Y, Hyundai Ioniq 5/6, Kia EV6, many others) | Can sustain higher charge power for longer before tapering | Low to moderate, assuming normal use | Check battery health report, look for balanced fast‑charging history, expect relatively stable capacity. |

| Early air-cooled | First‑gen Nissan Leaf and a few other pioneers | Often throttles quickly, especially on back‑to‑back sessions | High in very hot regions with frequent fast‑charging | Treat each car as an individual: insist on a capacity test, be realistic about reduced range. |

| Passive / minimal cooling | Some low‑range city EVs and plug‑in hybrids | Limited fast‑charging capability or none | Moderate; smaller packs can heat quickly | Understand daily range needs; these can still work well as short‑range commuters. |

Use this as a directional guide; individual vehicles still live and die by how they were driven and charged.

Cooling-focused checklist for used EV shoppers

Confirm the cooling architecture

Look up whether the specific model year uses liquid, air, or passive cooling. Sometimes automakers quietly improve cooling mid‑generation.

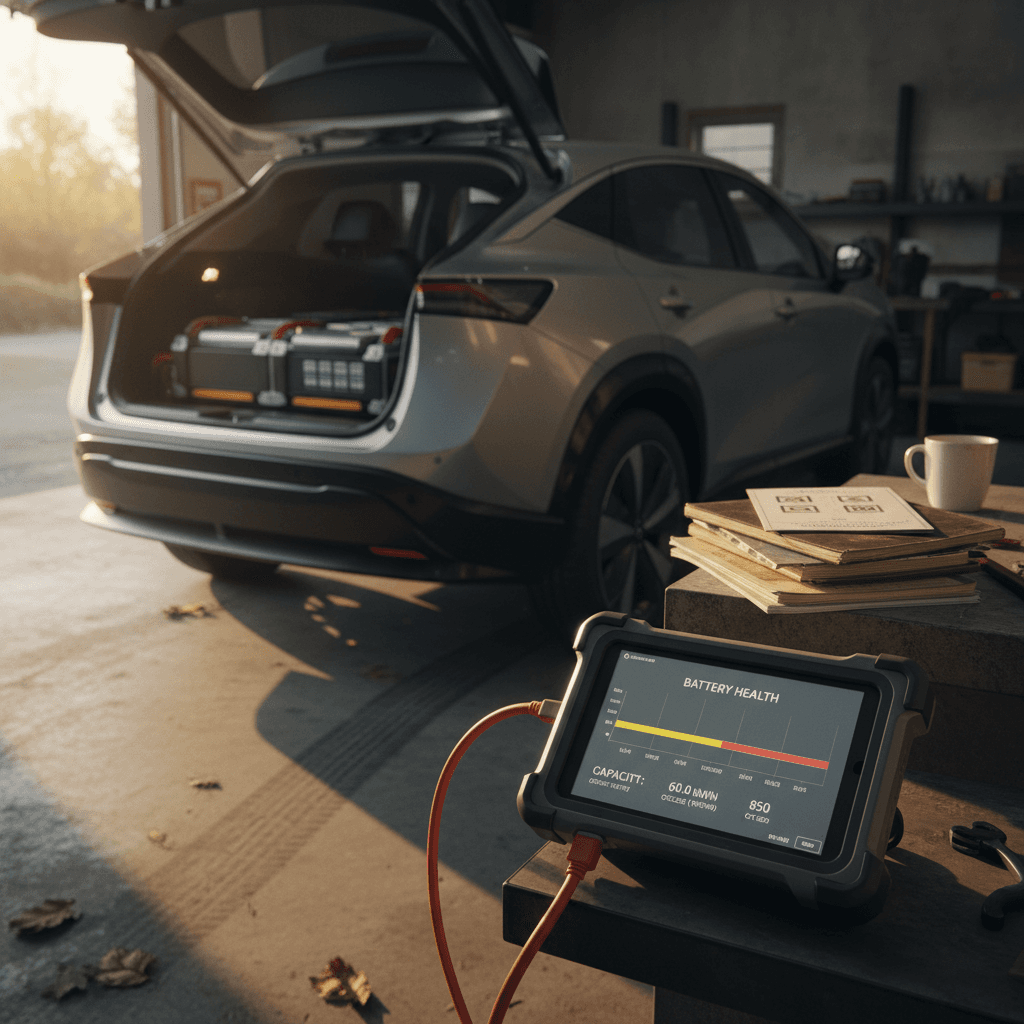

Get an objective battery health report

On Recharged, every car includes a <strong>Recharged Score</strong> with pack diagnostics. Elsewhere, ask for a dealer test or third‑party inspection.

Review climate and use history

A lightly used EV from a mild‑climate city may be a better bet than a similar‑mileage car that lived its life fast‑charging in the desert.

Test fast‑charging behavior if possible

If the seller allows, do a short DC fast‑charge session and watch how quickly the car tapers power. Abrupt early tapering can hint at thermal or aging issues.

In a combustion car, you worry about oil changes and timing belts. In an EV, your long‑term story is written by battery chemistry and thermal management.

EV battery cooling: frequently asked questions

Common questions about electric car battery cooling

Key takeaways for everyday drivers

You don’t need to be an automotive engineer to make smart decisions about electric car battery cooling. Focus on a liquid‑cooled pack if you can, treat heat as the enemy, and favor cars with transparent battery health data, especially on the used market. The cooling system is the quiet hero that lets your EV charge quickly, deliver honest range, and hold its value.

If you’re browsing used EVs, Recharged was built for exactly this moment. Every car comes with a Recharged Score Report, EV‑specialist support, and options for financing, trade‑in, and nationwide delivery, all designed to make battery health and cooling history less of a mystery, and EV ownership a lot more straightforward.